XW-120V120A Battery Pack Charge and Discharge Aging Cycle Machine

- Home

- Battery testing equipment

- Battery charge and discharge aging machine

- XW-120V120A Battery Pack Charge and Discharge Aging Cycle Machine

Model: XW-120V120AXCH

Max voltage: 120V

Max current: 120A

Channel: X, customized

Type: Energy regenerative

User interface: Computer software

Usage: For battery pack charge and discharge aging capacity testing

Certification: CE

MOQ: 1 pcs

Leading time: 10-15 days

Warranty: 1 year

- Description

- Parameters

The battery charge and discharge aging machine is an essential testing equipment primarily used for conducting charge and discharge cycle tests and aging treatments on batteries to evaluate their charge and discharge curves, capacity, durability, and safety.

The battery charge and discharge aging machine simulates the actual charge and discharge conditions of batteries and conducts long-term cycle tests. During the testing process, the equipment precisely controls parameters such as voltage, current, and temperature to mimic complex operating conditions in real-world applications. Simultaneously, the equipment continuously records various parameters and data, including voltage, current, temperature, and capacity, which are used to generate battery aging curves and performance reports.

![]()

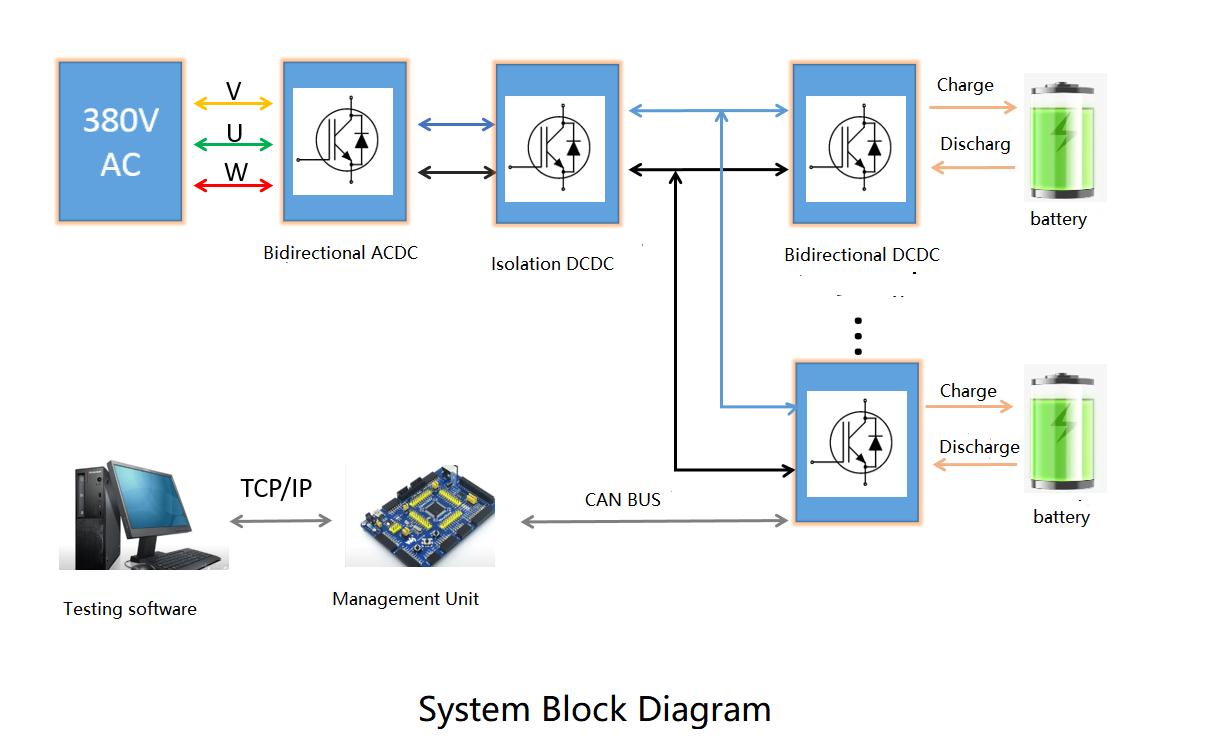

Upper computer: The upper computer software serves as the primary human-machine interaction tool, enabling functions such as device startup, shutdown, pause, and sequencing through the upper computer; the data of battery aging is primarily collected, processed, and output by the upper computer to provide customers with the required test results.

Middle computer: The middle computer is the central control management software for the device, executing calculations for the parameters of battery test such as capacity and electric quantity.

Bi-directional AC/DC + LLC isolated DC/DC: During charge, this functional module draws power from the power grid, regulates it through the bi-directional DC/DC, and charges the battery; during discharge, the functional module feeds the energy transferred from the bi-directional DC/DC back to the power grid.

Bi-directional DC/DC (Buck/Boost): This functional module is a non-isolated DC/DC, capable of outputting the current and voltage values required for battery charge and discharge, thereby executing constant current charge, constant voltage charge, and constant current discharge.

![]()

◆ Employing high-frequency isolating mode, the complete system is isolated from the power grid, guaranteeing safe and stable system operation;

◆ The bi-directional AC/DC module utilizes space vector modulation technology and digital control, resulting in high voltage utilization and minimal current harmonic splitting;

◆ The internal conversion of dual-channel charge and discharge energy is achievable;

◆ The DC/DC module adopts advanced PID regulation technology and multiple protection mechanisms, guaranteeing the operation stability of the device;

◆ Energy feedback (efficiency of DC bus ≥ 92%): The energy-feedback type allows discharged battery energy to be returned to the power grid;

◆ The constant current and constant voltage mode switches seamlessly with no voltage or current impact, effectively preventing heat concentration of batteries caused by peak current, which can lead to battery tab delamination;

◆ Voltage and current sampling employs a four-wire system, guaranteeing high voltage sampling accuracy and long-term stability;

◆ The single-channel system possesses independent operation capabilities and supports multi-channel parallel output;

◆ The device supports barcode input for batteries and enables traceability of historical test data.

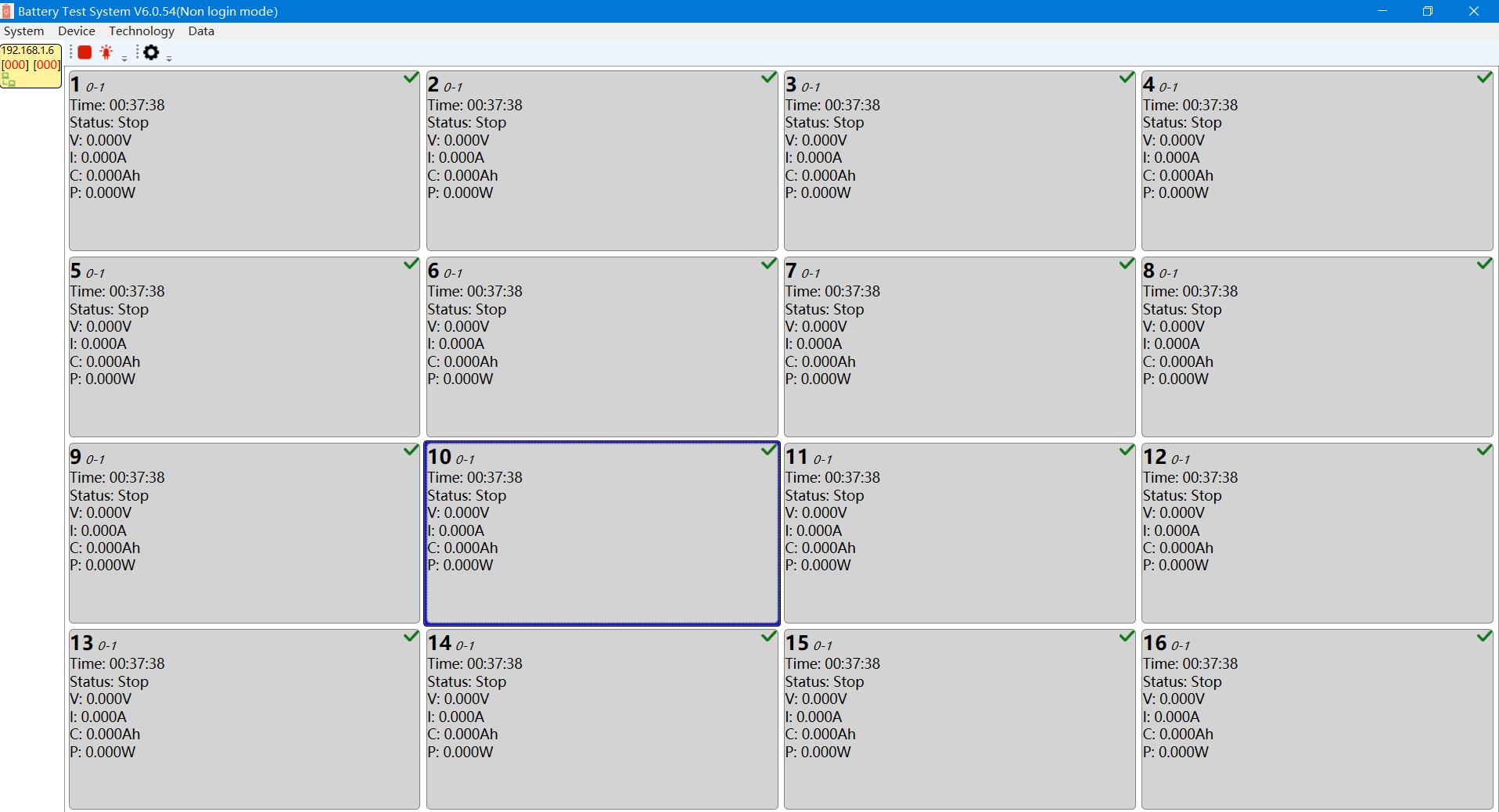

Main Interface

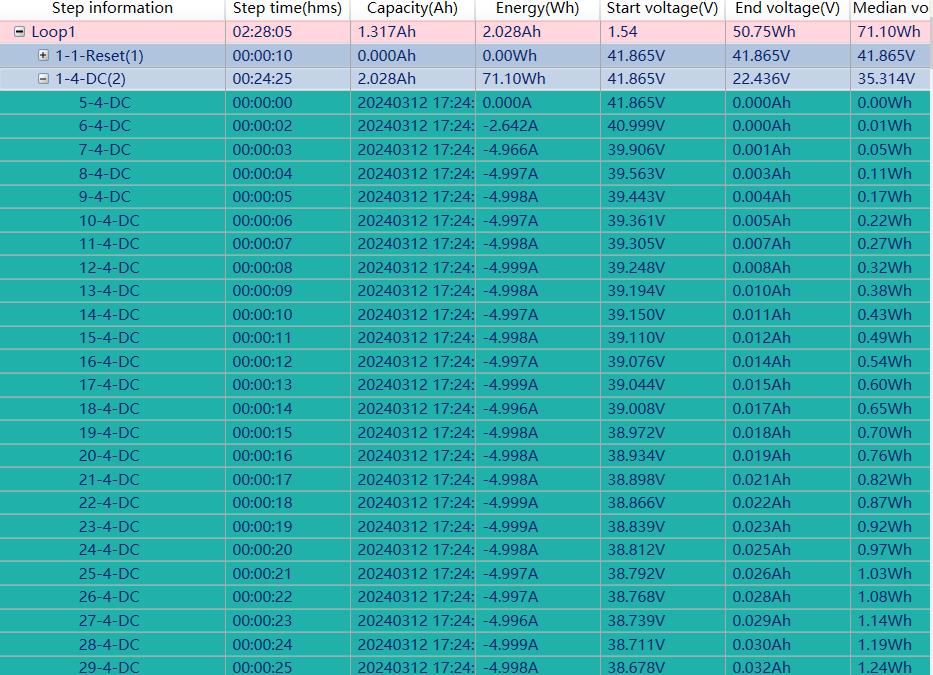

Each channel is independently controlled, with independent editing of processes of each channel. Channel status can be quickly identified by the background color of the upper computer interface.

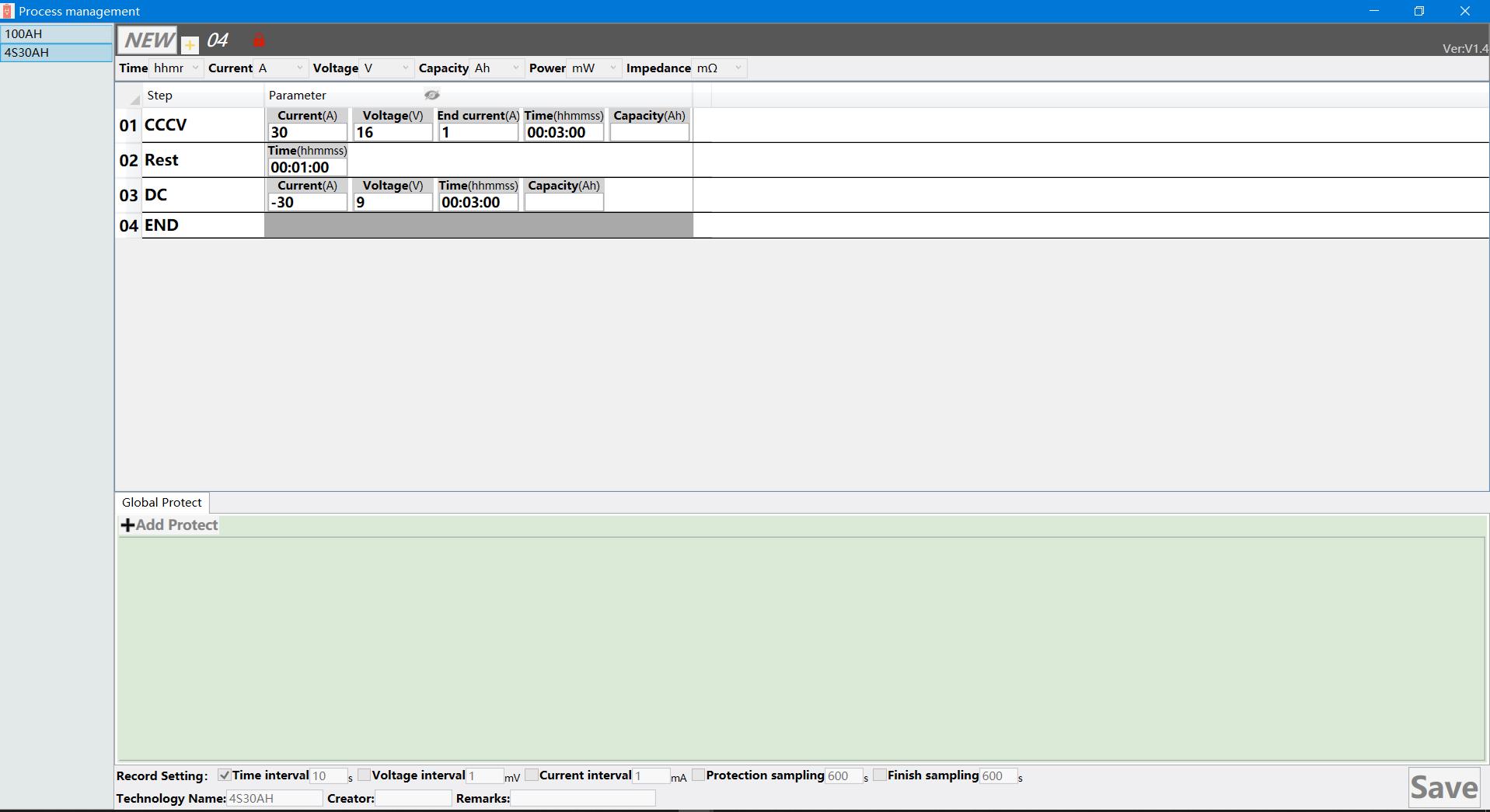

Step Setting Interface

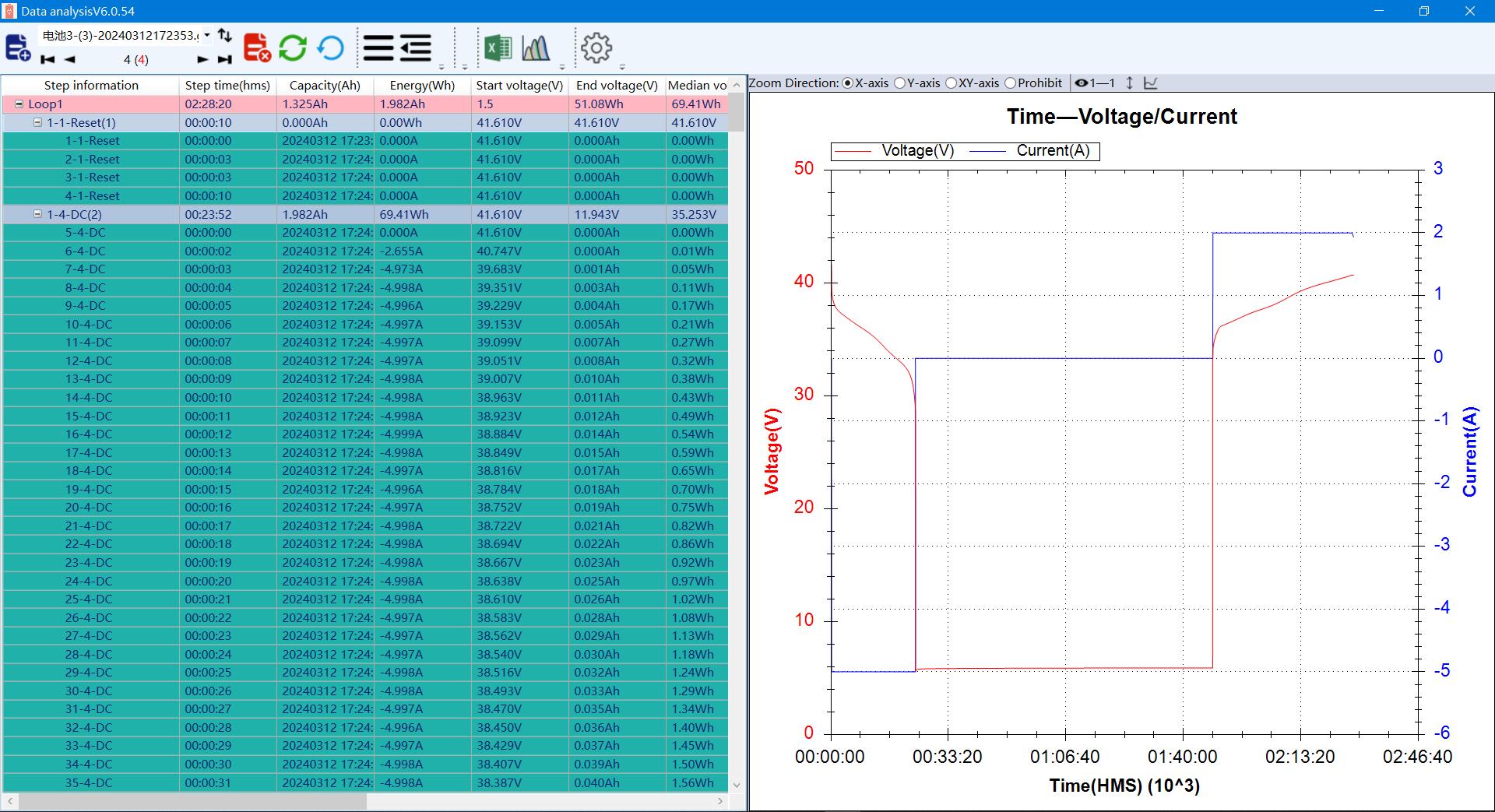

Users can customize the content of the X-axis and Y-axis for data comparison analysis, supporting up to four curve data simultaneously.

After well selecting the curve content, the corresponding color can be configured in the list. The curve can be freely zoomed and moved, and double-clicking data in the data table will map it to a data point on the curve.

Detailed Record

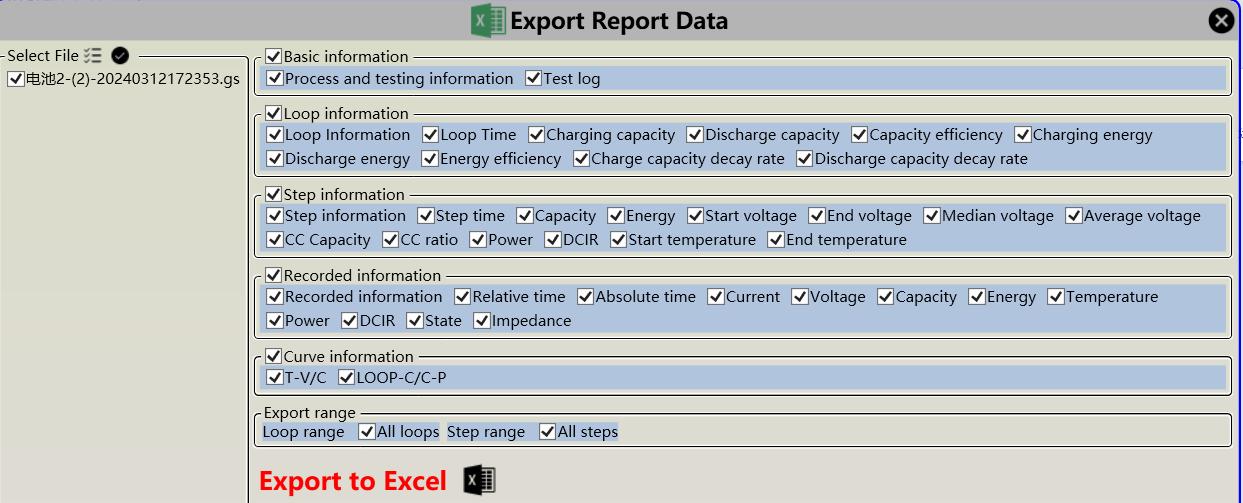

Data and curve processing: The system can directly export data to CSV and EXCEL, and save curves as images directly. Furthermore, users can customize the display items of the list based on their needs, including cycle data, process data, and detailed data, as well as customize the name of export file.

| Item | Parameter |

| Model | XW-120V120AXCH |

| Number of channels | X, customized |

| Maximum power | 48KW |

| System function | 1. Battery cycle life test

2. Battery capacity test 3. Battery charge/discharge characteristics test 4. Battery charge retention ability test 5. Battery charge/discharge efficiency test 6. Battery over charge/over discharge rate endurance test |

| AC input interface | 1. Input three-phase five-wire system: AC304V~456V,50/60HZ.

2. Input current:73A; 80A-3P circuit breaker is recommended. 3. Frequency: 50Hz 4.THD≦3% 5. Power factor > 0.99 (rated power) 6. Charge efficiency: <=85%,Discharge efficiency: <=84% (the whole machine) 7. Feedback efficiency of bus: 92% |

| Charging voltage | DC 0~120V The voltage range that can be detected and set during charging is up to 120V |

| Discharge voltage | DC 120~8V The range of voltages that can be detected and set when discharging, with a minimum voltage of 8V |

| Charging current | DC 0~120A The range of current that can be detected and set during charging, the maximum current is 120A |

| Discharge current | DC 0~120A Current range that can be used to detect and set when discharging, the maximum current is 120A |

| Voltage accuracy | ±0.05% of F.S±0.05% of F.D |

| Current accuracy | ±0.05% of F.S±0.05% of F.D |

| Power accuracy | ±0.05% of F.S±0.05% of F.D |

| Current response time | Current hardware response time: ≤50ms |

| Time setting range | 1,000 minutes/step |

| Voltage and current detection | Four-wire connection |

| Data recording frequency | ≥1000ms |

| Output DC voltage resolution | 1mV |

| Minimum output current | 50mA |

| Minimum discharge voltage | 8V (voltage of device port) |

| Output DC current resolution | 1mA |

| Channel parallel connection | Support max 4 channels in parallel |

| Data export mode | The data can be exported to EXCEL and chart files, providing a variety of data analysis curves and data lists such as charge and discharge curve, capacity attenuation rate, cycle life curve, charge and discharge voltage, current, capacity-time, etc.. |

| Data storage mode | Users can customize the file name and data saving path, with data saved in file format. |

| Working mode of main channel | Charge: constant current (CC) charge, constant voltage (CV) charge, constant current and constant voltage (CCCV) charge. |

| Discharge: constant current discharge (CD), constant current and constant voltage discharge (CVD) | |

| Communication mode | LAN (TCP/IP) |

| BMS communication method | CAN/RS485(Modbus)(Customized) |

| Test data recording | Voltage, current, time, capacity, electric quantity |

| Input protection | Over-voltage, over-current, open phase, over-temperature, protection alarm and islanding protection; |

| Output protection | Over-voltage, over-current, short circuit, reverse connection, capacity, temperature, no output when the battery voltage is not detected; |

| Software protection | Power failure data protection, power-on resume, over-voltage and over-discharge protection, over-current and under-current protection, capacity protection, over-temperature protection, abnormal protection against voltage trend, abnormal protection against current trend, abnormal protection against current fluctuation, abnormal protection against voltage fluctuation, abnormal protection against rising speed of charging voltage and abnormal protection against falling speed of discharging current; |

| Number of cycles | Max. 10,000 times |

| Cooling mode | Forced air cooling |

| Dimensions (W*D*H) | 650*600*1600mm |

| Ambient temperature | -20℃~50℃ |

| Humidity | 10-90%RH |