Microporous Copper Aluminum Foil Solid State Battery Lithium Battery

- Home

- Battery material

- Battery Supporting Materials

- Microporous Copper Aluminum Foil Solid State Battery Lithium Battery

Model:CC

Thickness:8μm / 10μm / 12μm / >12μm

Width:187mm / 260mm / 350mm (OEM*)

Aperture:0.25mm / 0.35mm / 0.40mm (OEM*)

Spacing:0.6mm / 0.8mm (molded) / 1mm

Porosity: 10%-40% (e.g., 17%: 0.35mm+0.8mm)

Thickness: 99.6μm

Compaction Density: 3.31g/cm³

MOQ: 100pcs

Leading time: 5-8 working days

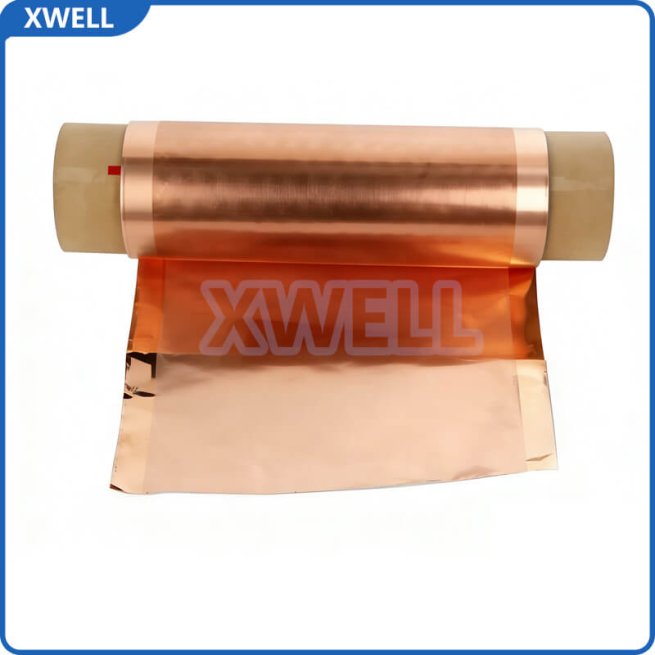

Microporous Copper Foil Aluminum Foil Solid-state Battery Lithium Battery For New Energy Power Battery-grade Current Collector Porous Punching

1. Product Overview

Our precision-engineered micro-perforated copper/aluminum foils are designed for next-generation solid-state and lithium-ion batteries. With customizable porosity (up to 40%) and zero burrs, these foils enhance electrolyte infiltration and electrode kinetics while maintaining structural integrity.

Key Applications:

- Solid-state batteries

- High-energy-density lithium batteries

- Power batteries for EVs/ESS

2. Customizable Specifications

| Parameter | Options |

|---|---|

| Thickness | 8μm / 10μm / 12μm / >12μm |

| Width | 187mm / 260mm / 350mm (OEM*) |

| Aperture | 0.25mm / 0.35mm / 0.40mm (OEM*) |

| Spacing | 0.6mm / 0.8mm (molded) / 1mm |

| Porosity | 10%-40% (e.g., 17%: 0.35mm+0.8mm) |

Note: Non-standard sizes require mold development.

3. Performance Advantages

A. Enhanced Electrode Compaction

| Parameter | Conventional Foil | 17% Microporous Foil |

|---|---|---|

| Ternary Cathode (15μm Al) | ||

| Thickness (μm) | 99.6 | 97.06 (-2.55μm*) |

| Compaction Density (g/cm³) | 3.31 | 3.41 (+3%) |

| Graphite Anode (10μm Cu) | ||

| Thickness (μm) | 103.75 | 102.16 (-1.7μm*) |

| Compaction Density (g/cm³) | 1.60 | 1.72 (+7.5%) |

Theoretical thickness reduction due to porosity.

B. Superior Rate Performance

| Metric | Conventional Foil | 17% Microporous Foil |

|---|---|---|

| 1C Capacity (mAh/g) | 146.0 | 149.2 (+2.2%) |

| 5C/1C Retention | 39.20% | 47.53% (+21.2%) |

C. Lower Internal Resistance

| Material | Internal Resistance (mΩ) |

|---|---|

| Conventional Foil | 46.0 |

| 17% Microporous | 39.8 (-13.5%) |

4. Why Choose Our Foils?

Porosity Optimization: Balanced open-area ratio for ionic/electronic conductivity.

Process Compatibility: Works with standard rolling pressure (4MPa tested).

Performance Gains: Higher energy density, faster charging, and longer cycle life.

Quality Assurance: Zero burrs, ISO-certified production.

5. Order Information

- MOQ: 1 roll (custom widths available)

- Lead Time: 2-4 weeks (standard), 6-8 weeks (OEM molds)

- Packaging: Vacuum-sealed to prevent oxidation.

Contact us for technical datasheets or sample requests!