XW-LCA Automatic Laser Prismatic Battery Cell Cleaning Machine

- Home

- Prismatic battery pack machine

- Prismatic cell laser cleaning machine

- XW-LCA Automatic Laser Prismatic Battery Cell Cleaning Machine

Model: XW-LCA

Laser power: 50W/100W

Clean size: 700*500mm

Battery type: Prismatic

Usage: for cell positive and negative terminal cleaning

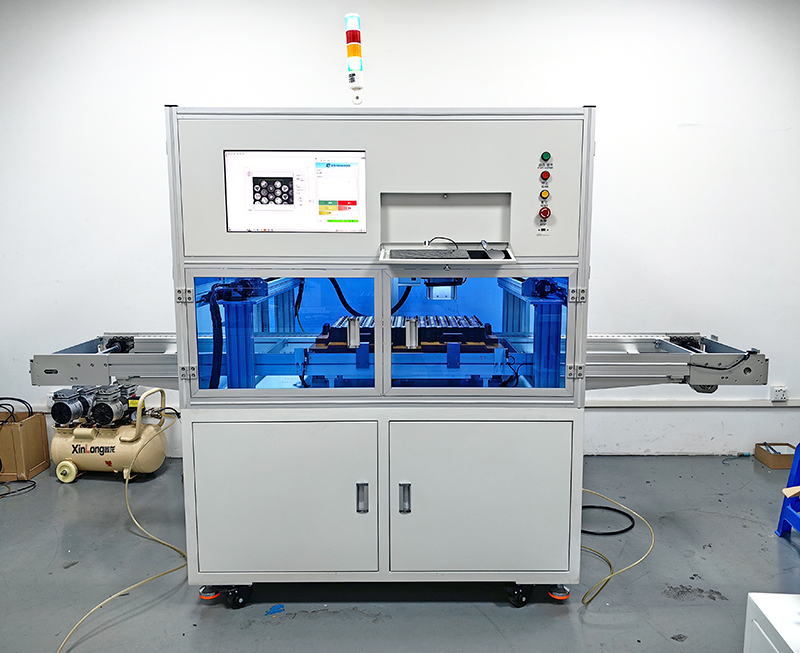

Type: Full automatic with conveyor

Certification: CE

MOQ: 1 pcs

Leading time: 10-15 days

Warranty: 1 year

- Description

- Parameters

- Video

The laser battery cleaning machine is an advanced piece of equipment specifically designed to clean and process various types of batteries, especially lithium batteries, includes cylindrical cell, pouch cell, prismatic cell and battery pack.

Its working principle is based on the combination of laser technology and efficient cleaning methods, providing an efficient and precise cieaning solunon tor the batery manutacturing process, it uses laser technoloev for cleaning, irradiating the battery surface with high-energy laser beams to quickly and accurately remove dirt, grease, oxides and other impurities.

Laser cleaning machines play an important role in the battery manufacturing and assembly industry, improving cleaning effciency and quality and ensuring the stability and reliability of battery products, its efficient cleaning process also helps ensure battery performance and longevity, as well as compliance with environmental reauirements.

![]()

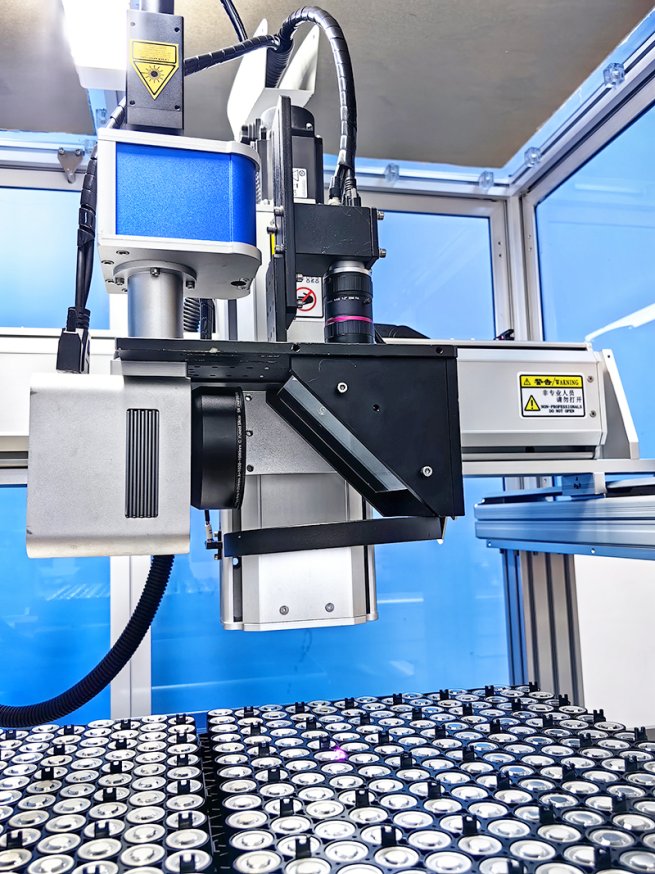

1. Assembly line operation, equipped with conveyor and automatic clamping tools, one-time programming, fully automatic cleaning of battery terminals.

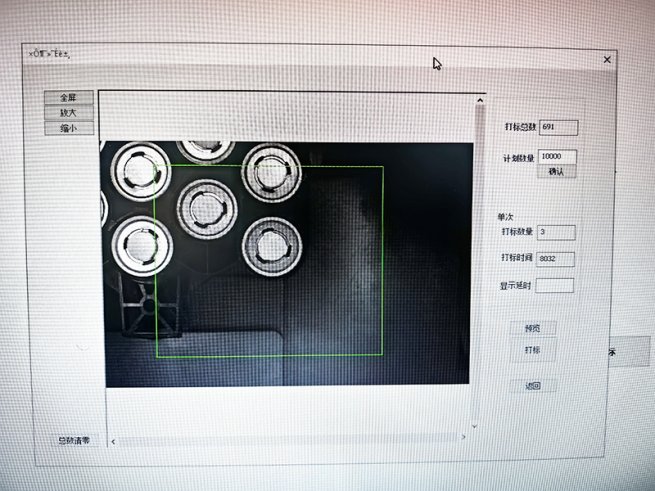

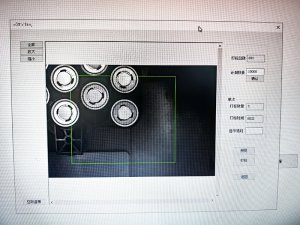

2. Optional CCD visual identity, automatic identity the battery terminal, higher cleaning accuracy.

3. Good beam quality, single mode output, beam diameter 10mm after collimation, beam divergence angle 0.24mrad.

4. After focusing, the spot diameter is small, and the peak power density at the working point is very high.

5. High pulse repetition rate, ideal for high-speed cleaning

6. It adopts maintenance-free main oscillation power amplification technology and seed light source pulse generation technology,it can run continuously for 24 hours, maintenance free, saving maintenance and running cost, and greatly improving the input output ration of users.

7. Very high over all electro-optical conversion efficiency, no bulky power system.

Battery loading by conveyor

Fully automatic cleaning all cells in pack

CCD battery identification

| Item | Parameter |

| Model | XW-LCA |

| Laser power | 50W/100W |

| Laser wavelength | 1060-1070nm |

| Repeat frequency | 1-4000KHZ |

| Beam quality | <1.6 |

| Standard cleaning range | 700*500mm |

| Conveyor size | 2800*500mm |

| Cleaning line depth | <0.2mm |

| Minimum focus spot | 0.005mm |

| CCD visual identity | Optional |

| Working mode | Pulse and Continuous |

| Max single pulse energy | 1.8mJ |

| Power adjustable range | 10-100% |

| Power | 2Kw |

| Voltage | AC220V150Hz |

| Cooling | By air |

| Size | 2810*1240*1880mm |

| Weight | 600kg |