For some time, lithium batteries have been concerned about safety hazards due to the sudden high temperature during charging and how to solve the problem.

On November 10, the reporter learned from the Institute of Modern Physics, Chinese Academy of Sciences that the research team of the Institute’s Materials Research Center, in cooperation with Lanzhou University, Guangdong Provincial Laboratory of Advanced Energy Science and Technology and other related teams, relying on the large scientific facility Lanzhou Heavy Ion Accelerator, recently used ion track technology to develop a new process for preparing polyimide high-temperature resistant diaphragms for high-performance lithium-ion batteries, which will help improve the safety of lithium batteries and their charging.

Schematic diagram of the safety characteristics of the polyimide ion track membrane (left) and traditional porous diaphragm (right) in this study. Institute of Modern Physics, Chinese Academy of Sciences/Photo

This important research progress in the field of lithium battery materials was recently published in the professional academic journal “American Chemical Society Nano Journal” (ACS Nano). The first author and corresponding author of the paper are both from the Institute of Modern Physics, Chinese Academy of Sciences.

They introduced that the diaphragm, as one of the key components of lithium-ion batteries, has the function of isolating the positive and negative electrodes and conducting lithium ions, which is crucial to the safety of the battery. At present, the energy density of commercial lithium-ion batteries can reach 300 watt-hours per kilogram, and is expected to be further improved. However, while pursuing higher energy density of lithium-ion batteries, safety issues cannot be ignored. Traditional polyolefin separators have poor thermal stability and uneven pore structure. They are prone to shrinkage at high temperatures and cause internal short circuits in the battery and thermal runaway.

Polyimide is considered an ideal choice for high-safety separators due to its excellent thermal stability, high mechanical strength and good chemical stability. Therefore, it is very important to conduct in-depth research on polyimide, develop polyimide separators with uniform pore structure and achieve controllable preparation, in order to give full play to the role of separators in improving battery safety.

In this study, the research team of the Institute of Modern Physics, Chinese Academy of Sciences and its collaborators developed a new process for preparing high-temperature resistant polyimide diaphragms based on ion track technology based on the Lanzhou heavy ion accelerator. The prepared diaphragms have obvious advantages over traditional polyolefin diaphragms. Their mechanical strength is as high as 150.6 MPa, and they have excellent high-temperature resistance (the structure does not shrink at 450 degrees Celsius), narrow pore size distribution (pore size standard deviation <6%), and vertical arrangement of pore structure (tortuosity is 1).

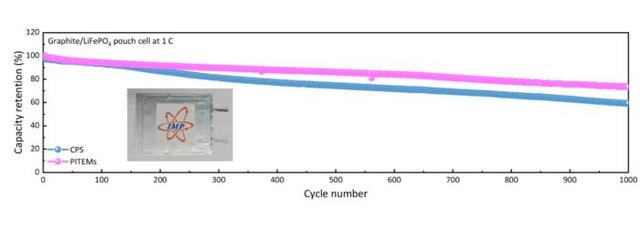

The research team pointed out that under the condition of 3 milliamperes per square centimeter, the lithium/lithium symmetric battery using polyimide high-temperature resistant diaphragm can be stably cycled for 1200 hours, and uniform and dense lithium deposition can be achieved on the surface of lithium metal electrode, indicating that it has excellent lithium dendrite inhibition ability. In addition, the lithium iron phosphate soft-pack battery using this diaphragm can be stably cycled 1000 times at room temperature, with a capacity retention rate of 73.25%, and exhibits excellent high-temperature performance, and can work normally at an ambient temperature of 150 degrees Celsius.

Comparison of the long-cycle performance of the lithium iron phosphate soft-pack battery studied in this study. Photo courtesy of Institute of Modern Physics, Chinese Academy of Sciences

The research team said that their latest research results provide new ideas for the development of reliable high-temperature resistant and high-performance lithium-ion battery separators and processes, which will become one of the effective ways and means to improve the safety of lithium-ion batteries.