Pouch Cell Heat Press Machine for Lithium Battery Research

- Home

- Battery laboratory machine

- Pouch cell laboratory machine

- Pouch Cell Heat Press Machine for Lithium Battery Research

Model: XW-GYJ100/XW-GYJ200/XW-GYJ300

Usage: Heat Press

Type: Automatic

Certification: CE

MOQ: 1 pcs

Leading time: 10-15 days

Warranty: 1 year

- Description

- Parameters

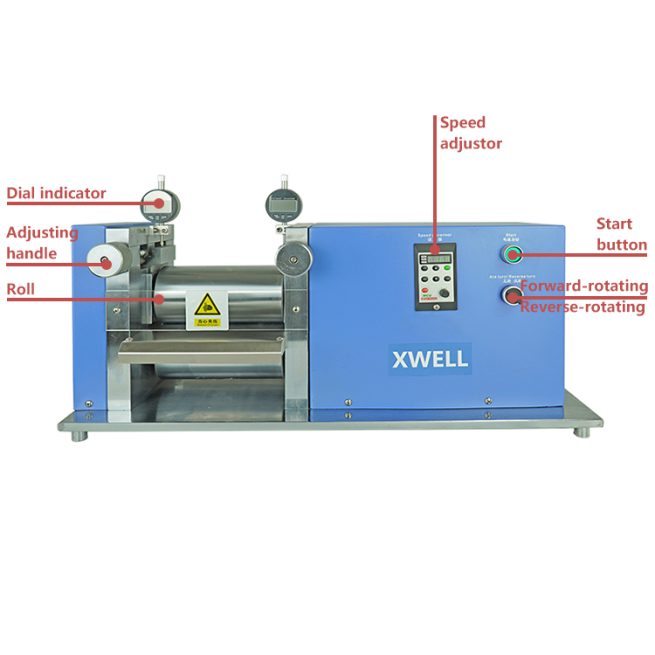

XW-GYJ Rolling Press Machine. It has dual rollers and dual grade micrometer. This lab roll press machine is an ideal rolling press for adjusting thickness and increasing active material density of the electrode in Li-Ion batteries research after coating and drying.

This machine is a compact hot rolling press machine mainly serves for pressing samples in the lab or other applications in the material research especially for increasing active material density of the electrode in Li-Ion batteries research after coating.

This Lab roll press machine is mainly used in the laboratory lithium battery materials, small amount of precious metals such as gold and silver materials, copper, aluminum and other non-ferrous metal materials manually suppressed.

![]()

![]()

1.Hot rolling, thermostat control temperature, digital display.

2.Can choose working with or without heating.

3.Roll made from hardened tool steel (HRC≥62) with Cr electroplated coating.

4.Using inclined block adjustment tableting clearance, the self-locking is good, high precision of adjustment.

5.High precision rolling roller, cylindrical degree≤±2um.

6.The gear rotation of roller press.

7.The thickness of the tablets and the speed can be adjusted. Beautiful appearance.

8.Automatic electric rolling, reversing operation.

9.Small size, easy to operate, flexible and efficient.

| No | Model | XW-GYJ100/200/300 | |||

| 1 | Voltage | 110V – 220V AC, 50/60Hz | |||

| 2 | Roller | 1. Dimensions: 96 mm(Dia.)*100/200/300 mm(W) 2. Material: ceramic coated on hardened tool steel with HRC > 62, which have much hard than Cr plated roller and provides better surface roughness. 3. Ceramic coating material: 97% is chromic oxide; 3% is aluminum oxide, calcium oxide and magnesium oxide 4. High resistance to corrosion, acid and alkalinity, and reduce metallic contamination |

|||

| 3 | Structure | 1. Heavy duty steel frame, gears and handle 2. φ96 mm Rollers made from hardened tool steel (HRC>62) with Cr electroplated coating 3. Dual micrometer for accurate thickness adjustment in the range 0~2 mm maximun. |

|||

| 4 | Rolling Press Accuracy | ≤±0.005 mm | |||

| 5 | Rolling Press Thickness | 0~2 mm adjusted with dial gauge | |||

| 6 | Cylindrical Degree | ≤±2um | |||

| 7 | Rolling Press Width | 0~300mm, can be customized | |||

| 8 | Rolling Speed | 0~40mm/s, can be adjusted | |||

| 9 | Rolling Temperature | 0~200℃, temperature can be adjusted, digital display | |||

| 10 | Dimensions(L*W*H) | 385 *245 *355 mm | |||

| 11 | Weight | 55KG | |||

| 12 | Standard Configuration | An Allen wrench, two dial indicator, one feeler | |||

| 13 | Warranty | One year limited manufacture warranty with lifetime support | |||

| 14 | Application Notes | The XW-GYJ roller is specially designed for battery R&D in terms of its advantages as affordable, compact and precise. 1. Must use acetone to clean and dry rollers’ surfaces after each use to avoid rusting. 2. Apply anti-rust lubricant on roller surface if machine were to be unused for a long period of time. 3. The minimum thickness of the rolled sheet should depend on the physical property of the materials. Here are some results from our test: |

|||

| Electrode | Size W*L | Original thickness | Finished thickness | ||

| LiFePO4 double sides | 50*260mm | 0.205mm | 0.07mm | ||

| LiMn2O4 double sides | 50*260mm | 0.205mm | 0.07mm | ||

| Copper foil + graphite (single side) | 75*240mm | 0.09mm | 0.04mm | ||