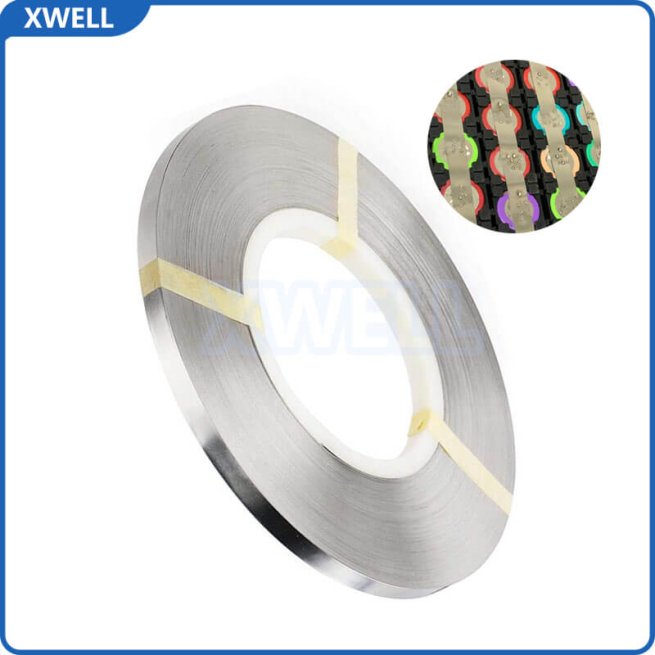

Nickel-plated steel strip (0.1/0.12/0.15/0.2mm thickness), nickel sheet and nickel strip – special for 18650 lithium battery connecting tabs

- Home

- Battery material

- Battery Pack Accessories

- Nickel-plated steel strip (0.1/0.12/0.15/0.2mm thickness), nickel sheet and nickel strip – special for 18650 lithium battery connecting tabs

Material:SPCC Steel with Nickel Plating

Thickness Options:0.1mm / 0.12mm / 0.15mm / 0.2mm

Applicable Batteries:18650, 21700, 26650, 32650 cylindrical lithium batteries

Core Performance:High conductivity, corrosion resistance, easy welding

Customization:Width, length, and plating thickness customizable

Working Temperature: -40℃ ~ +85℃

MOQ: 1kg

Leading time: 5-8 working days

Nickel-plated steel strip (0.1/0.12/0.15/0.2mm thickness), nickel sheet and nickel strip – special for 18650 lithium battery connecting tabs

Product Overview

Our SPCC nickel-plated steel strip is a premium connector designed for 18650, 21700, 26650, 32650 cylindrical lithium batteries. Made of high-quality SPCC substrate with uniform nickel plating, it balances excellent electrical conductivity, corrosion resistance, and mechanical strength, ensuring stable current transmission and reliable connection for battery packs. Ideal for power tools, energy storage devices, e-bikes, and consumer electronics, it’s a core component for high-performance battery assemblies.

Key Specifications

| Item | Details |

|---|---|

| Material | SPCC Steel with Nickel Plating |

| Thickness Options | 0.1mm / 0.12mm / 0.15mm / 0.2mm |

| Applicable Batteries | 18650, 21700, 26650, 32650 cylindrical lithium batteries |

| Core Performance | High conductivity, corrosion resistance, easy welding |

| Customization | Width, length, and plating thickness customizable |

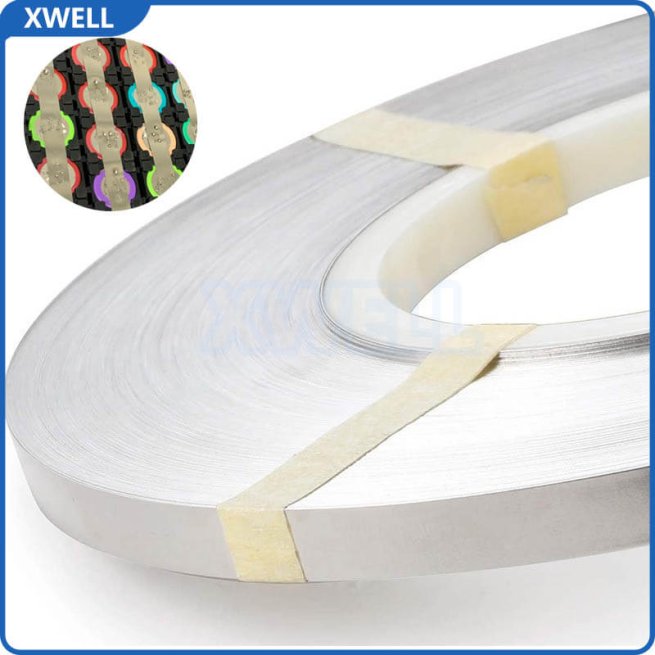

Core Advantages

-

Premium Material: SPCC substrate ensures toughness; uniform nickel plating enhances conductivity and anti-corrosion, extending battery pack lifespan.

-

Multi-Spec Adaptation: 4 standard thicknesses (0.1-0.2mm) fit 18650/21700/26650/32650 batteries, meeting diverse pack design needs.

-

Reliable Connection: Low contact resistance for stable current transmission, avoiding overheating and ensuring battery safety.

-

Easy Processing: Weldable, cuttable, and bendable, suitable for automated and manual battery assembly.

-

Cost-Effective: Balances performance and cost, ideal for mass production of battery packs.

Application Fields

Widely used in lithium battery pack assembly for:

-

Consumer electronics (power banks, laptops, digital devices)

-

Electric tools, e-bikes, electric scooters

-

Energy storage systems, backup power supplies

-

Portable power stations, electric toys

Customization & Supply

-

Customize width, length, and nickel plating thickness per drawings/samples.

-

Free samples for quality testing (shipping fee at buyer’s cost; refundable on bulk orders).

-

MOQ: 1000pcs for standard specs; bulk lead time 7-12 working days.

-

Global shipping via DHL/FedEx/UPS with secure packaging.

Contact Us

For quotations, samples, or customization (thickness, size, quantity), contact our team. We reply within 24 hours with personalized solutions!