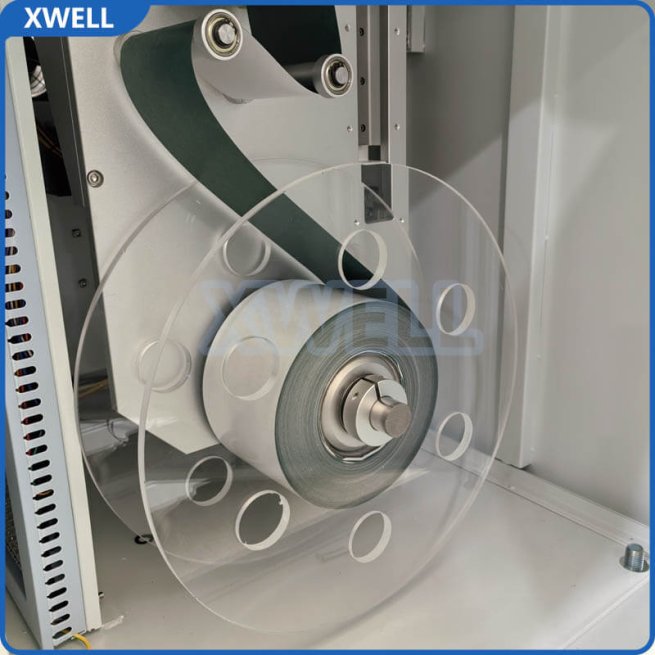

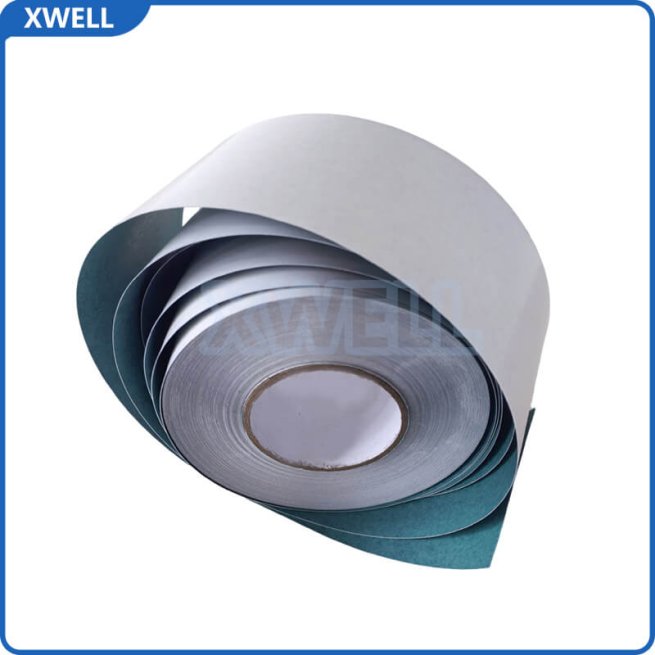

Insulation Highland Barley Paper for XWELL Battery Insulation Paper Sticking Machine

- Home

- Battery material

- Battery Pack Accessories

- Insulation Highland Barley Paper for XWELL Battery Insulation Paper Sticking Machine

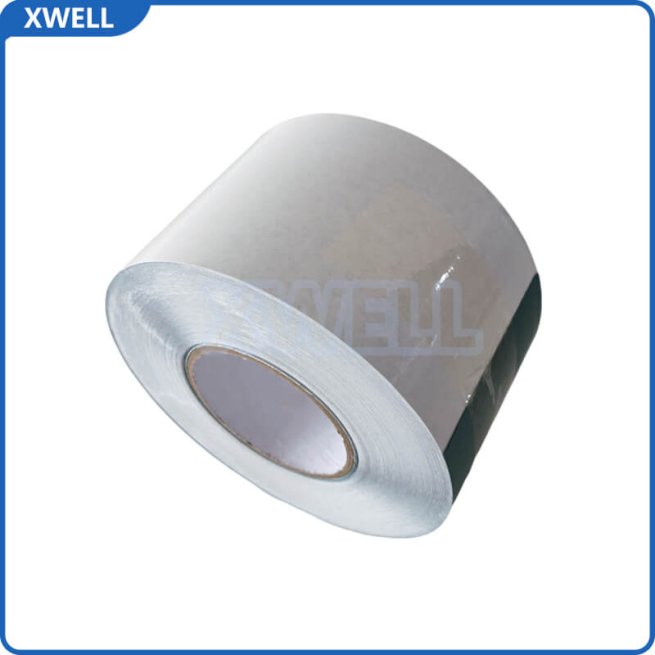

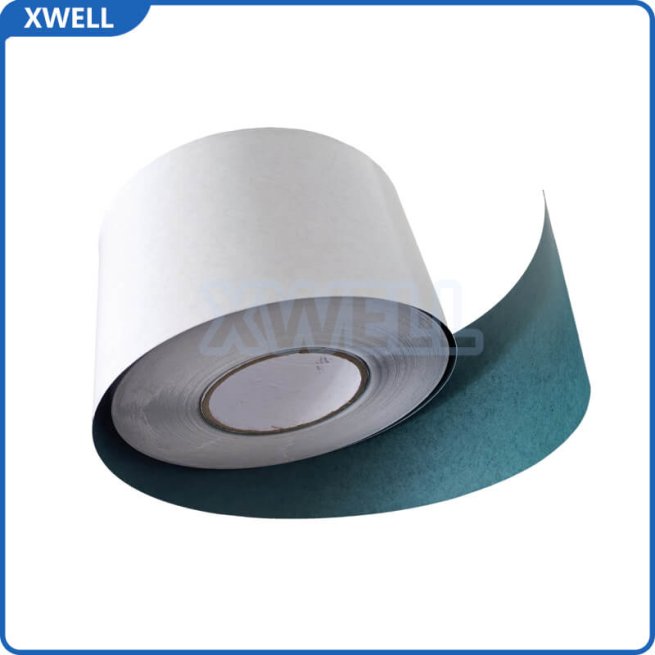

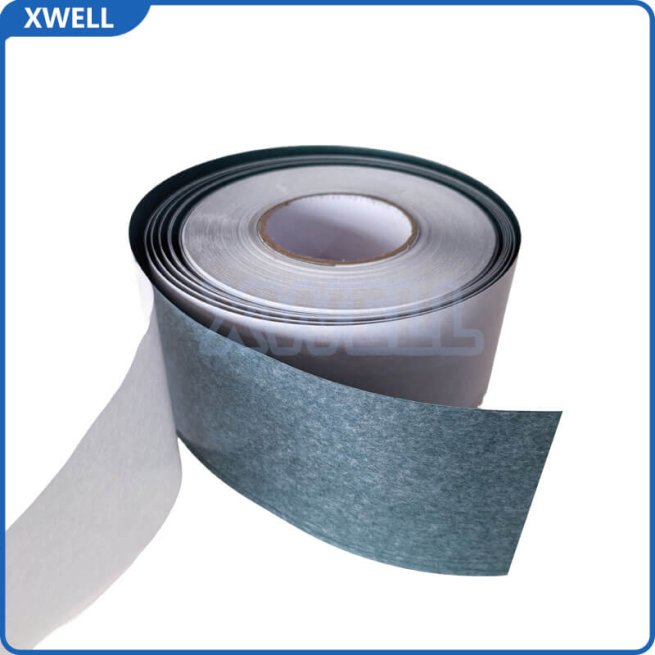

Material:Fluoroplastic-Processed Barley Paper

Thickness:0.2mm

Width:99mm

Length:100m

Temperature Resistance:130℃

Voltage Resistance:4000v

MOQ: 10pcs

Leading time: 5-8 working days

Insulation Highland Barley Paper for XWELL Battery Insulation Paper Sticking Machine

Product Overview

This high-performance insulation highland barley paper is specially developed to match the XWELL Battery Insulation Paper Sticking Machine, featuring excellent compatibility and adaptability for automated battery production lines. Crafted from a composite of cyan wood pulp insulation paper and polyester film, bonded with acid-free heat-resistant adhesive, it delivers reliable electrical insulation, mechanical flexibility, and stable performance—perfectly meeting the precision sticking requirements of XWELL equipment.

Performance Parameters

- Heat Resistance: Continuous working temperature up to 130℃, heat resistance grade E/B, no bubbling or adhesive flowing under high-temperature conditions.

- High-Voltage Resistance: Withstands 4000V voltage, effectively blocking electrical conduction and preventing short circuits.

- Mechanical Performance: Strong tensile strength, flexible for longitudinal and transverse bending, wear-resistant and durable for long-term use.

- Environmental & Physical Traits: Eco-friendly acid-free adhesive, non-toxic, thickness 0.2mm (customizable), no bubbling or glue bleeding.

Key Advantages

- Superior Insulation & Voltage Resistance: 4000V high-voltage protection and 130℃ heat resistance ensure stable performance in harsh electrical environments, avoiding insulation failure.

- Flexible & Durable Composite Design: Combines wood pulp paper’s insulation and polyester film’s dielectric strength, with strong tensile force and bending flexibility for irregular surfaces and gaps.

- Adhesive-Backed Option for Easy Installation: Single-sided adhesive design enables peel-and-stick application, no extra tools or glue needed, improving assembly and maintenance efficiency.

- Flexible Procurement & Customization: Sold by the meter, width can be customized freely to fit different project needs; 0.2mm standard thickness, with optional thickness adjustment available.

- Eco-Friendly & Safe: Acid-free adhesive, non-toxic and eco-friendly, complying with global environmental regulations; no bubbling or glue flow, ensuring clean and safe application.

- Multi-Scene Versatility: Suitable for both battery insulation and electrical equipment maintenance, with wide applicability across industries.

Technical Specifications

| NO. | Properties | Units | Values | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | Nominal Thickness | mm | 0.15 | 0.17 | 0.2 | 0.25 | 0.3 | 0.5 |

| 2 | Thickness Allowed Tolerance | mm | ±0.02 | ±0.02 | ±0.03 | ±0.03 | ±0.03 | ±0.03 |

| 3 | Nominal Grammage | g/m² | 155 | 180 | 210 | 255 | 300 | 600 |

| 4 | Film Nominal Thickness | μm | 25 | 25 | 25 | 25 | 25 | 25 |

| 5 | Tensile Strength (MD) | N/10mm | ≥100 | ≥110 | ≥120 | ≥120 | ≥150 | ≥150 |

| 6 | Tensile Strength (XD) | N/10mm | ≥70 | ≥75 | ≥80 | ≥95 | ≥105 | ≥105 |

| 7 | Elongation (MD) | % | ≥2 | ≥2 | ≥2 | ≥2 | ≥2 | ≥2 |

| 8 | Elongation (XD) | % | ≥8 | ≥8 | ≥8 | ≥8 | ≥8 | ≥8 |

| 9 | Electric Breakdown Voltage | KV | ≥2 | ≥3 | ≥4 | ≥5 | ≥5.5 | ≥6 |

Applications

Ideal for 18650 and other cylindrical/prismatic lithium battery packs. It serves as inter-cell insulation gaskets, sealing pads, and component separators in automated sticking processes via XWELL machines, effectively preventing short circuits and significantly enhancing battery pack safety and stability.

Contact Us

For detailed quotations, samples, or customization inquiries, please reach out to our professional team. We reply within 24 hours to provide personalized solutions and technical support, helping you enhance battery safety and production efficiency.