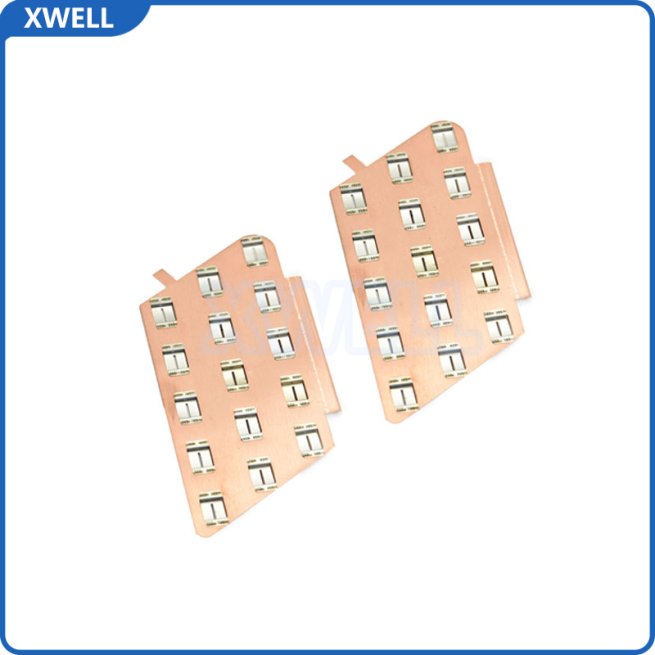

Cu-Ni Busbar 0.5MM Copper + 0.15MM Nickel Composite Sheet 22.5mm Welding

- Home

- Battery material

- Battery Pack Accessories

- Cu-Ni Busbar 0.5MM Copper + 0.15MM Nickel Composite Sheet 22.5mm Welding

Material:Cu + Ni nickel plated steel strip

Type: 0.3MM Thickness Copper +0.15MM Nickel Copper Nickel Composite Sheet

Width:Customized

Length:Customized

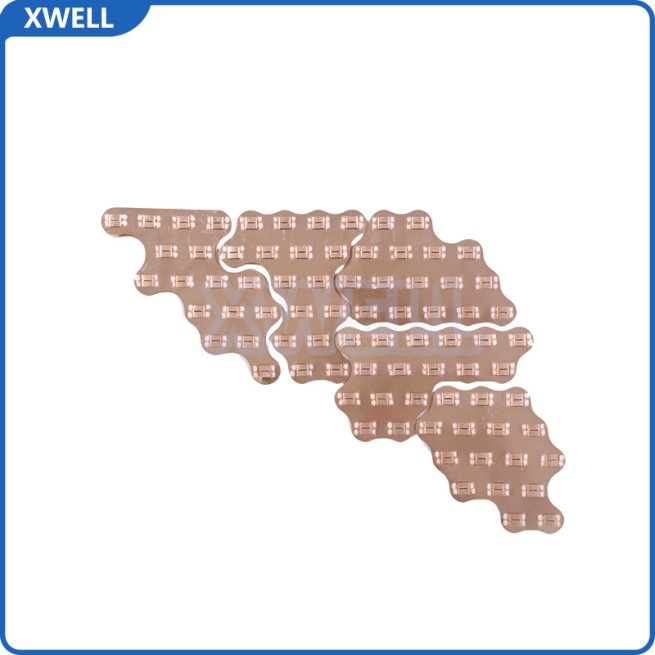

Point to point welding distance: 22.5mm

MOQ: 100pcs

Leading time: 5-8days

Category: Battery Pack Accessories

Customized High Current Cu-Ni Busbar

Our Cu-Ni Busbar features a 0.5MM pure copper layer + 0.15MM copper-nickel composite layer, offering optimal balance between electrical/thermal conductivity and corrosion resistance. Designed for 21700/18650/32650 battery configurations with 10S8P setup, it provides flexible voltage and current solutions while incorporating grounding protection for enhanced safety.

Key Features

- Enhanced conductivity & corrosion resistance: Nickel layer prevents copper oxidation, extending component lifespan while maintaining stable performance in harsh environments.

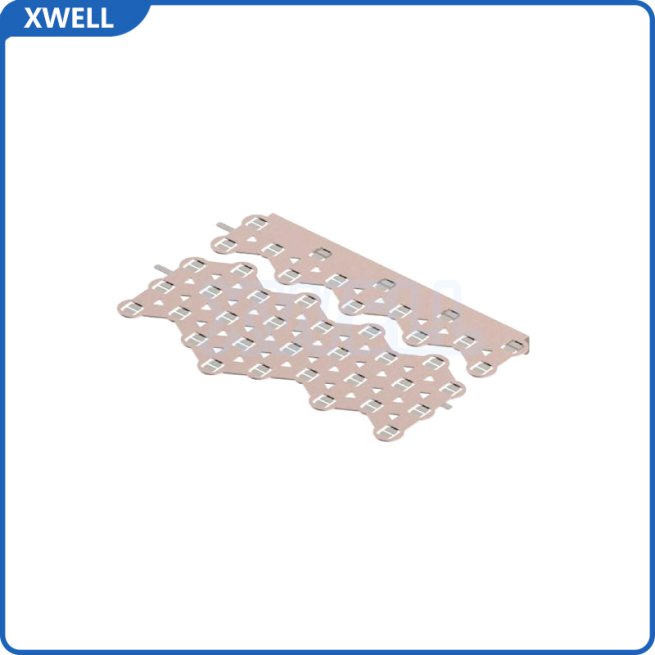

- Improved mechanical strength: Nickel coating acts as barrier layer, preventing metal diffusion while enhancing circuit reliability and weldability.

- Reduced signal loss: Superior surface flatness minimizes current transmission loss and signal reflection for stable electronic performance.

- Exceptional environmental adaptability: Maintains stable chemical properties in humidity, high temperature, and corrosive conditions.

Technical Specifications

| Brand Name | Xwell |

|---|---|

| Model Number | 21700 Copper Nickel Composite Sheet |

| Place of Origin | Guangdong, China |

| Material | Copper+Nickel |

| Color | Copper |

| Copper Thickness | 0.3mm, 0.5mm |

| Nickel Plated Steel Strip Thickness | 0.15mm |

| Point to Point Welding Distance | 22.5mm |

| Length | OEM |

| Application | 21700 Battery Pack Connection |

Customization Options:

- Available in pure aluminum, red copper, or copper-aluminum composite materials

- Specify required length, width, thickness, and hole-to-hole distance

- Compatible with supporting battery brackets or custom drawings

Why Choose Our Cu-Ni Busbar?

- Quality guarantee: Pre-production samples provided before mass production

- Safety compliant: Rigorous final inspection before shipment

- Fully customizable: Special colors and sizes available for OEM projects

- Cost-effective: Competitive bulk pricing for large orders