Custom Color Highland Barley Paper with Adhesive Backing – 180℃ High-Temp Resistance and 0.08mm–0.3mm Thickness for Battery Insulation

- Home

- Battery material

- Battery Pack Accessories

- Custom Color Highland Barley Paper with Adhesive Backing – 180℃ High-Temp Resistance and 0.08mm–0.3mm Thickness for Battery Insulation

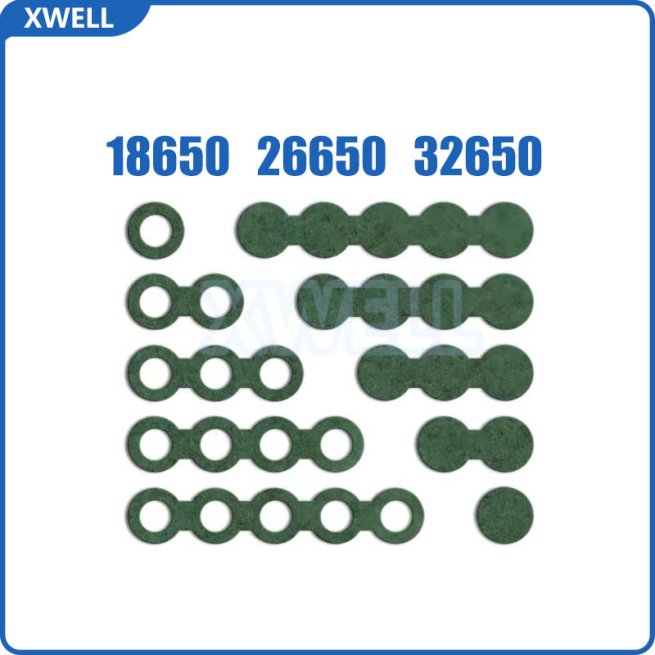

Model:18650

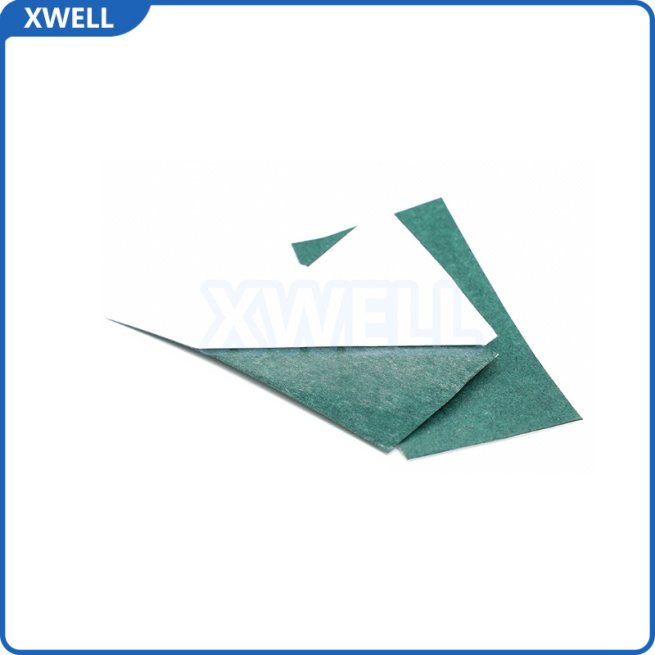

Material:Natural highland barley fiber + acrylic adhesive

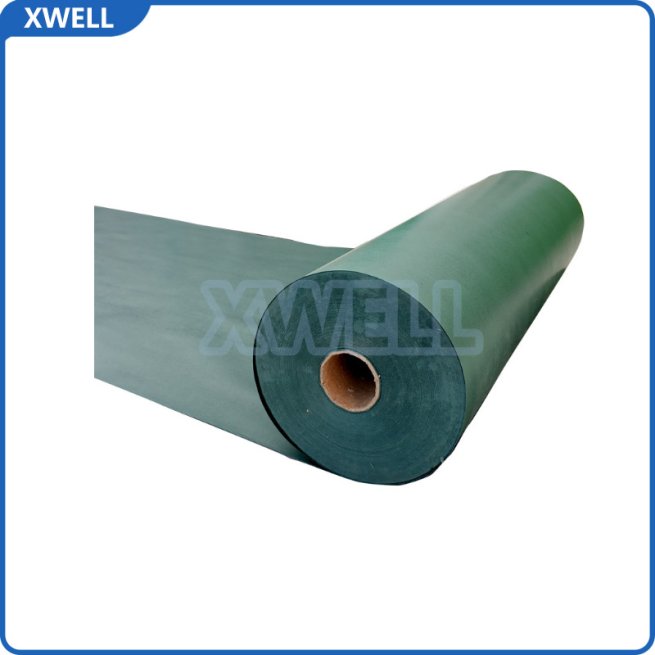

Color:Deep Green (as shown in images)

Thickness:0.08mm–0.3mm

Dimensions:Custom roll widths (10mm–100mm) and pre-cut sheet sizes (per cell specs)

Temperature Range:-20°C to +200°C (operational)

Adhesive Type:Standard acrylic adhesive (high temp) or silicone adhesive (for -60℃ to 200℃ extreme environments)

Key Applications:18650 hollow-cell batteries, EV batteries, power tools

MOQ: 100pcs

Leading time: 5-8 working days

Category: Battery Pack Accessories

Custom Color Highland Barley Paper with Adhesive – High-Temp Resistant for 18650/21700/26650/32650 Batteries

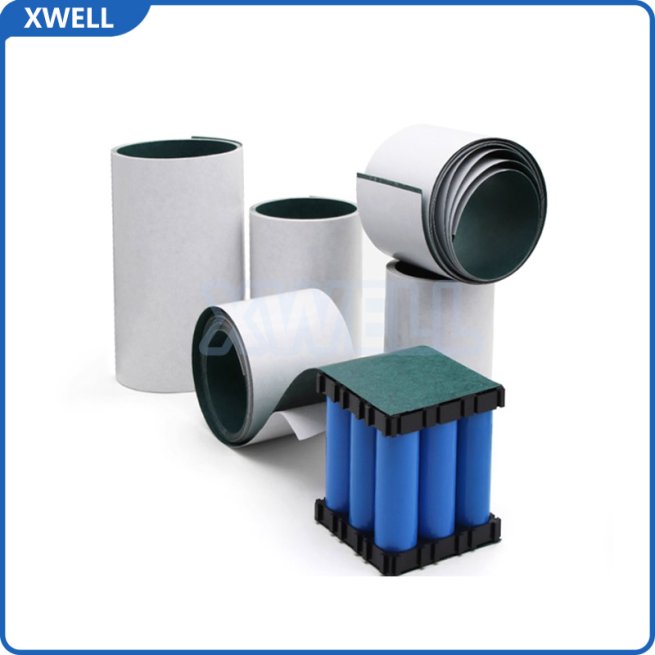

When assembling cylindrical lithium battery packs (18650, 21700, 26650, 32650), reliable insulation, heat resistance, and easy assembly are essential. Our Custom Color Highland Barley Paper combines extreme high-temperature resistance, strong pre-applied adhesive, and customizable colors for visual differentiation. Made from natural highland barley fiber, this solution streamlines assembly, enhances safety, and meets brand or module identification needs.

Core Advantages

| Advantage | Key Benefit for Battery Pack Manufacturers |

|---|---|

| Customizable Colors | Available in red, blue, green, black, white, or brand colors—enables visual sorting and reduces assembly errors |

| 180℃ High-Temp Resistance | Withstands continuous use at 180℃ (short-term up to 220℃), outperforming standard PET or kraft paper |

| Strong Adhesive Backing | High-tack acrylic adhesive bonds firmly to battery casings; resists peeling under vibration or temperature cycles |

| Natural & Eco-Friendly | Made from renewable highland barley fiber—halogen-free, non-toxic, and RoHS/REACH compliant |

| Thin & Space-Saving | 0.08mm–0.2mm thickness saves critical space in compact battery packs without compromising insulation |

Technical Specifications

| Specification | For 18650 Cells | For 21700 Cells | For 26650 Cells | For 32650 Cells |

|---|---|---|---|---|

| Compatible Cell Size | 18mm (diameter) * 65mm (length) | 21mm * 70mm | 26mm * 65mm | 32mm * 65mm |

| Material | Natural highland barley fiber + acrylic adhesive | |||

| Color Options | Custom (red/blue/green/black/white) or standard natural | |||

| Temperature Resistance | Continuous: 180℃; Short-term: 220℃ | |||

| Adhesive Performance | Peel strength ≥0.5N/cm (to aluminum) | Peel strength ≥0.5N/cm (to aluminum) | Peel strength ≥0.6N/cm (to aluminum) | Peel strength ≥0.6N/cm (to aluminum) |

| Electrical Insulation | Dielectric strength ≥10kV/mm | Dielectric strength ≥10kV/mm | Dielectric strength ≥12kV/mm | Dielectric strength ≥12kV/mm |

| Standard Thickness | 0.1mm / 0.15mm | 0.1mm / 0.15mm | 0.15mm / 0.2mm | 0.15mm / 0.2mm |

| Standard Form | Roll (50m/roll, width 20mm) or pre-cut sheets (20mm*70mm) | Roll (50m/roll, width 24mm) or pre-cut sheets (24mm*75mm) | Roll (50m/roll, width 28mm) or pre-cut sheets (28mm*70mm) | Roll (50m/roll, width 34mm) or pre-cut sheets (34mm*70mm) |

Application Scenarios

- Consumer Electronics: 18650 battery packs for power banks, laptops, and flashlights—thin design fits compact enclosures

- Power Tools: 21700/26650 packs for cordless drills and grinders—high-temp resistance handles heavy-duty discharge heat

- Electric Mobility: 26650/32650 packs for e-scooters and electric bikes—color-coding simplifies module maintenance

- Energy Storage: 32650 packs for solar storage—eco-friendly material aligns with green energy goals

Customization & Order Details

| Customization Item | Available Options |

|---|---|

| Color | Any Pantone color (minimum order: 5 rolls) |

| Dimensions | Roll width: 10mm–100mm; Pre-cut sheet size: Per your cell specs (±0.1mm precision) |

| Thickness | 0.08mm–0.3mm (adjustable for insulation/spacing requirements) |

| Adhesive Type | Standard acrylic or silicone adhesive (for extreme environments) |

| Packaging | Standard: Moisture-proof bags + cartons (50m/roll); Custom: Small test rolls or branded packaging |

Quality Assurance & Support

- Certifications: RoHS, REACH, and UL 94 V-0 (flame retardant)

- Testing: Each batch undergoes heat resistance, adhesive peel strength, and insulation performance tests

- MOQ & Lead Time: Standard colors: MOQ 5 rolls (ships in 2–3 days); Custom colors: MOQ 5 rolls (ships in 5–7 days)

- After-Sales: Free color samples and test rolls; 6-month warranty for quality issues

Need help matching the right thickness or color to your battery pack? Contact us today for a detailed quote!