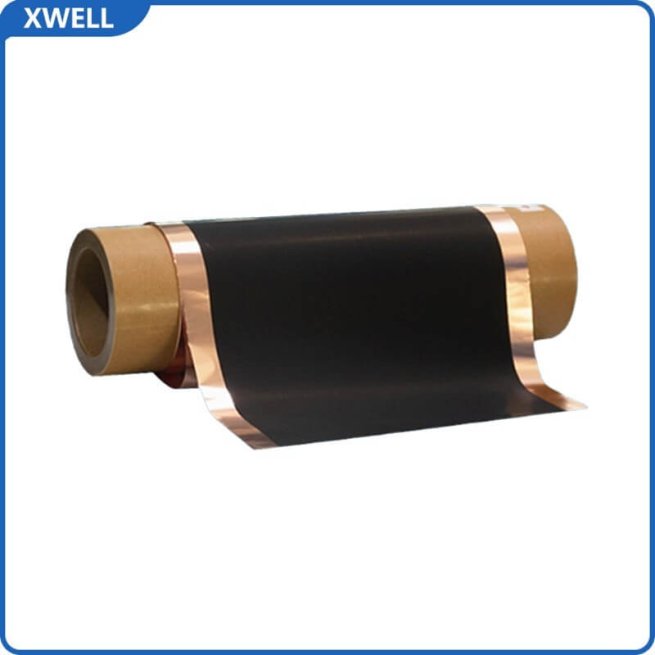

Single Sided Double Sided Carbon Coated Copper Foil Lithium Sulfur Battery

- Home

- Battery material

- Lithium Ion Battery Raw Material

- Single Sided Double Sided Carbon Coated Copper Foil Lithium Sulfur Battery

Model:Carbon-Coated Copper Foil

Coating Thickness:1μm (single side)

Surface Resistivity:<30Ω/25μm²

Total Width: 227±1mm

Base Foil Thickness:10±1.0μm (copper)

Copper Purity: >99.99%

Total Thickness: 12±1μm (post-coating)

MOQ: 1m

Leading time: 5-8 days

Single-sided Carbon-coated Copper Foil University Experimental Lithium Battery Current Collector Double-sided Carbon-coated Copper Foil Lithium-sulfur Battery Grade Copper Foil

1. Product Overview

Our Carbon-Coated Copper Foil is a high-performance conductive substrate designed for lithium-ion battery anodes, particularly for high-energy-density applications. With a uniform carbon coating and ultra-high-purity copper base, this foil enhances electrode conductivity, adhesion, and cycle stability, making it ideal for EV batteries, energy storage, and consumer electronics.

2. Key Features

Superior Conductivity:

- Surface resistivity <30Ω/25μm² (low impedance for efficient charge transfer).

- Copper purity >99.99%!(MISSING) ensures minimal energy loss.

Mechanical Strength: - Tensile strength ≥265MPa and elongation rate ≤6.0%!(MISSING) (resists cracking during electrode processing).

Precision Coating: - Single-side carbon layer (1μm) + total thickness 12±1μm (uniform and controllable).

Customizable Dimensions: - Standard width: 260±1mm (coating width: 227±1mm).

3. Technical Specifications

| Parameter | Specification |

|---|---|

| Coating Thickness | 1μm (single side) |

| Surface Resistivity | <30Ω/25μm² |

| Total Width | 260±1mm |

| Coating Width (S1) | 227±1mm |

| Base Foil Thickness | 10±1.0μm (copper) |

| Copper Purity | >99.99%! |

| Total Thickness | 12±1μm (post-coating) |

| Tensile Strength | ≥265MPa |

| Elongation Rate | 22%!,(MISSING) ≤6.0%! |

4. Applications

- Lithium-Ion Batteries: Improves anode performance for silicon-carbon (Si-C) and graphite systems.

- High-Power Devices: Supports fast charging/discharging in EVs and drones.

- Thin-Film Electronics: Used in flexible circuits and sensors.

5. Why Choose Our Carbon-Coated Foil?

Enhanced Battery Life: Reduces delamination risks during cycling.

Process Compatibility: Suitable for slurry coating, calendering, and stacking.

Quality Consistency: Strict ±1μm tolerance control for industrial-scale production.