Ternary Anode Graphite Sheets with 450mah/g Capacity and 2mg/cm²/10mg/cm² Areal Density for Single/Dual-sided Coating Battery Applications

- Home

- Battery material

- Lithium Ion Battery Raw Material

- Ternary Anode Graphite Sheets with 450mah/g Capacity and 2mg/cm²/10mg/cm² Areal Density for Single/Dual-sided Coating Battery Applications

Model:Graphite

Size: 10*10cm

Specification:Customizable

Capacity: 450mah/g

Areal density: 2mg/cm²/10mg/cm²

MOQ: 5 pcs

Leading time: 5-9 days

SKU: Graphite Category: Lithium Ion Battery Raw Material

Ternary Anode Graphite Single/Dual-sided Coating Mass-produced Battery-grade Sheets

Our Ternary Anode Graphite Single/Dual-sided Coating Mass-produced Battery-grade Sheets are high-performance core components tailored for lithium-ion battery manufacturing, integrating excellent electrochemical properties, stable production quality, and flexible customization capabilities to meet the diverse needs of new energy battery applications.

Key Features

- Proven Graphite Material Performance: Made of high-purity graphite material with excellent electrical conductivity, stable cycle performance, and low volume expansion rate during charge-discharge processes.

- Dual Coating & Mass Production Readiness: Available in both single-sided and double-sided coating options to adapt to different battery structural designs (cylindrical, prismatic, pouch).

- Comprehensive Specifications & Customization: Covers a full range of standard specifications with flexible customization services including adjustments to coating thickness, sheet size, and areal weight.

Primary Applications

- Electric Vehicles: Ideal for passenger EVs, PHEVs, and light commercial vehicles

- Energy Storage Systems: Suitable for residential, industrial, and grid storage applications

- Industrial Batteries: Perfect for forklifts, AGVs, and backup power systems

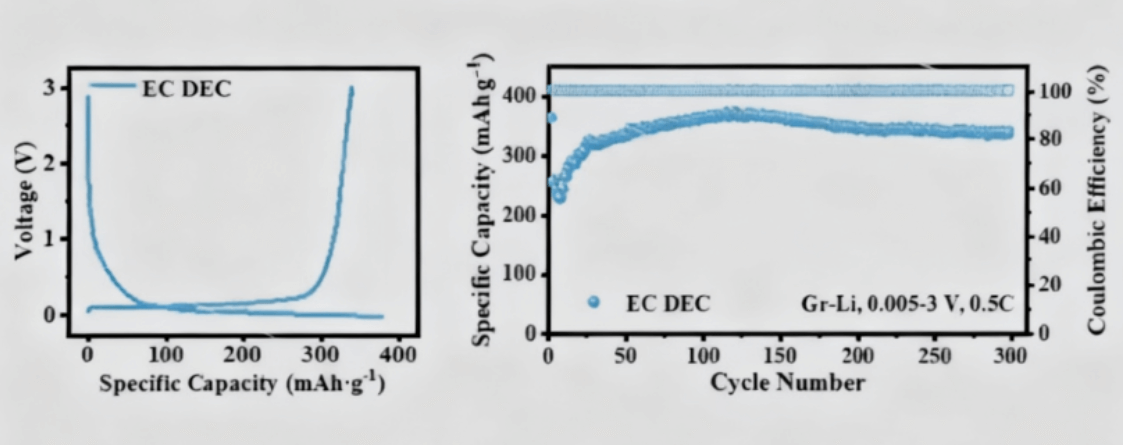

Electrochemical Performance

The cathode delivers high energy density (over 280Wh/kg) for demanding applications. For optimal performance, store in dry, low-humidity environments to prevent reactions with CO₂ and H₂O that could degrade performance.

Product Advantages

- Enhanced battery life with reduced delamination risks

- Excellent process compatibility for slurry coating, calendering, and stacking

- Strict quality control ensures consistency for industrial-scale production