XW-ACW Automatic Cylindrical Cell PVC Shrink Wrapping Machine

- Home

- Cylindrical battery pack machine

- Cylindrical battery PVC heat shrinking machine

- XW-ACW Automatic Cylindrical Cell PVC Shrink Wrapping Machine

Model: XW-ACW

Battery support: 18650/21700

Work speed: 50-60PPM

Battery type: Cylindrical

Usage: for battery cell PVC shrink wrapping

Type: Full automatic with conveyor

Certification: CE

MOQ: 1 pcs

Leading time: 20-30 days

Warranty: 1 year

- Description

- Parameters

- Video

Cylindrical battery wrapping machine is an integrated equipment for cylindrical battery PVC cover wrapping.This machine is controlled by PLC, AC servo motor to complete the precise positioning and cutting, loadingsurface pad, heat shrinking and cell collecting. About 3,600 finished batteries are produced per hour. Themechanical structure design is simple and elegant, and the performance is stable

This machine automatically loads the entire box. After resetting and restarting, the machine continues to operate automatically. During the pauses in intermittent motion, the pneumatic positioning clamps position the batteries. The servo feed system automatically applies heat shrink tubing to the batteries. Upon entering the next station, an insulating sheet is automatically punched out during the pauses and placed inside the heat shrink tubing. The sheet shrinks in the heat shrink oven, is then printed by the inkjet printer, and finally discharged through the unloading station.

![]()

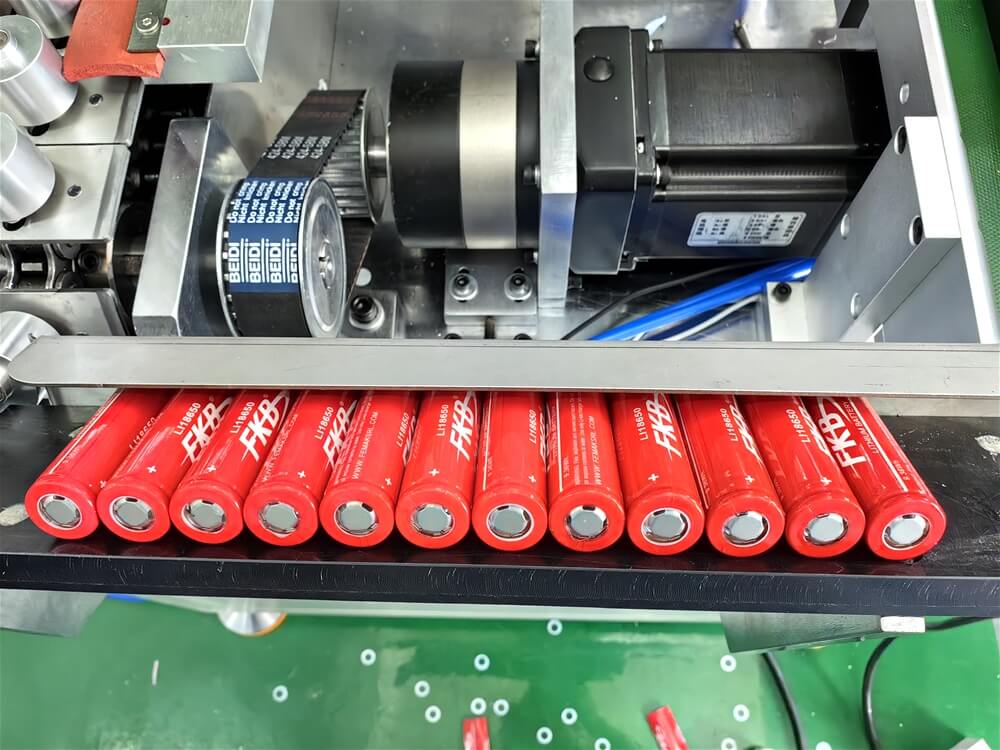

1) Full boxes of batteries are loaded into the automatic loading mechanism.

2) Equipped with an automatic receiving rack for automatic receiving.

3) Photoelectric sensors detect the presence of batteries online.

4) Automatic memory for missing locations.

5) Automatic application of heat shrink tubing, automatic punching of insulating gaskets, placement of the battery inserts, automatic heat shrinking, and automatic counting and display.

6) Servo-controlled heat shrink tubing feeding ensures high feeding accuracy.

7) The fan utilizes internal hot air circulation, automatically adjusting the temperature and minimizing temperature differences.

8) Batteries automatically rotate within the heat shrink oven to ensure uniform shrinkage and excellent roundness.

9) Short battery dwell time within the oven does not affect the performance of the PTC thermistors.

10) The battery conveyor belt is adjustable and can be adjusted to any speed.

11) Equipped with a color mark sensor, specifically for color film lamination, to control feeding accuracy.

![]()

1) Automatic Loading Mechanism: Batteries are loaded onto the box, and a speed-controlled motor delivers them in a rolling motion.

2) Material Conveyor: Material is conveyed by a speed-controlled motor and a stepper motor.

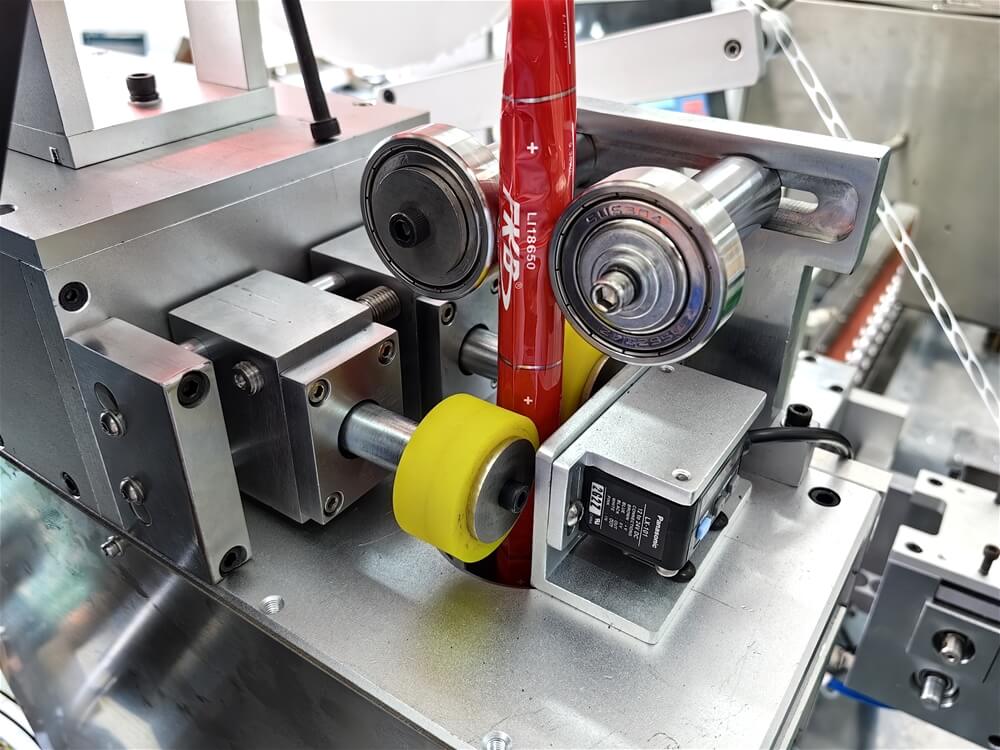

3) Sleeve Assembly: Consists of a servo motor and a cutting system, enabling each component to perform specific functions in its respective position.

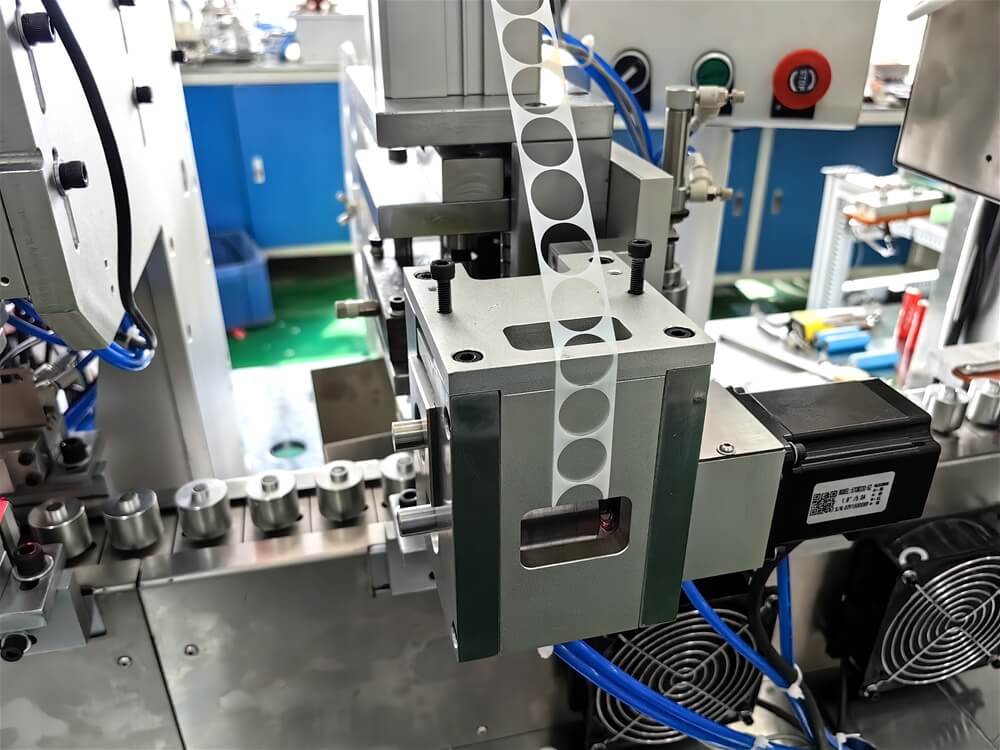

4) Punching and Pad Placement: Automatically punches and inserts insulating sheets.

5) Heat Shrink Unit: Heat shrink tubing automatically shrinks at a set temperature.

6) Electrical Control Unit: Primarily composed of an air switch, DC power supply, PLC, sensors, relays, etc.

7) Mechanical Structure: Consists of an aluminum profile, sheet metal cabinet, brackets, etc.

![]()

| Item | Parameter |

| Model | XW-ACW |

| Supply | AC220V/50Hz |

| Power | 5KW |

| Battery support | 14500,18650, 21700, 32650, 46800…(optional) |

| Function | Cell load, cover cut and wrap, pad cut and place, shrink, cell collection (optional) |

| Work speed | 50-60PPM |

| Pass rate | > 99.5% |

| Air source | 0.5-0.6MPa |

| Hot stove | 450mm |

| Temperatue | 135℃ (adjustable) |

| Weight | 1000kg |

| Size | 2000*1100*1700mm |