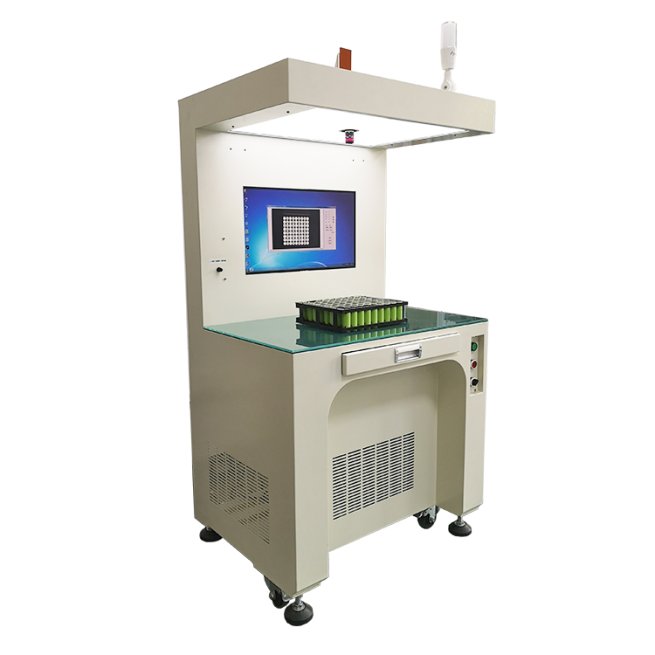

XW-CCD43 CCD Prismatic Cell Polarity Inspection Machine

- Home

- Prismatic battery pack machine

- Prismatic cell CCD polarity inspection machine

- XW-CCD43 CCD Prismatic Cell Polarity Inspection Machine

Model: XW-CCD43

Inspection size: 400*300mm

Battery type: Prismatic

Usage: for cell positive and negative direction checking

Type: Semi automatic

Certification: CE

MOQ: 1 pcs

Leading time: 10-15 days

Warranty: 1 year

- Description

- Parameters

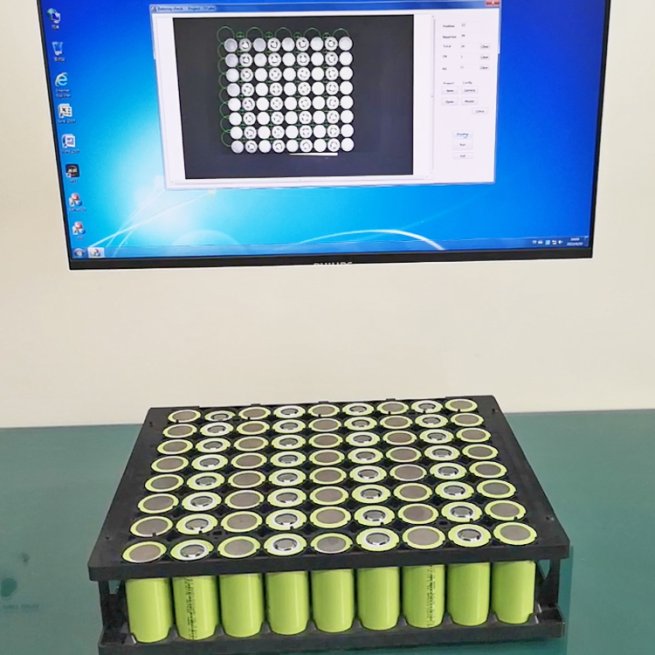

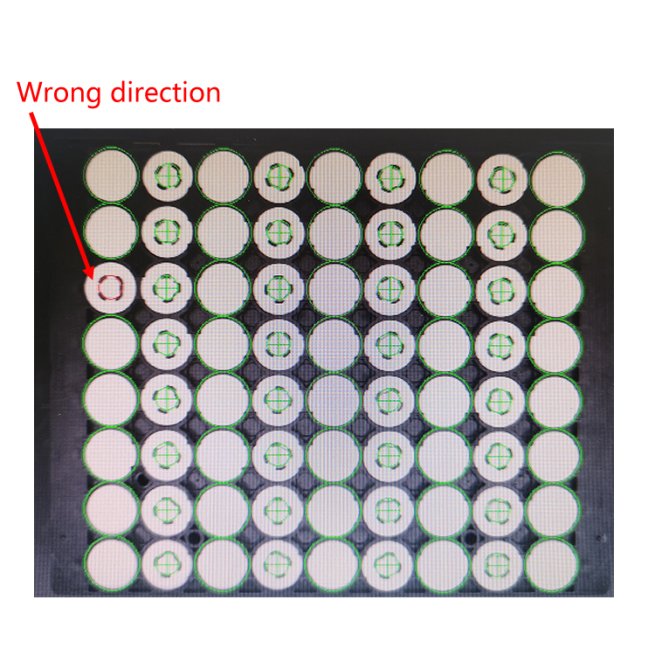

CCD visual inspection is used to judge whether the positive and negative poles of the battery cell are reversed, whether the battery cell position is misplaced, and whether the battery pack is reversed. The output result is given to the alarm.For the cylindrical cell, the camera is used to collect the positive and negative pole data, compare the number of positive and negative poles with the sample plate, quickly analyze the results (NG or OK), and mark the position of NG, so as to confirm the positive and negative poles before the battery pack enters the spot welding.and prevent defects caused by the wrong position of positive and negative poles.

![]()

1. Support manual loading and unloading and manual start detection mode.

2. High definition 6 megapixel fixed focus lens, the maximum detection range of the equipment is 400 mm x 300 mm, the detection performance is stable and the efficiency is high.

3. The programming is simple, the judgment standard can be set according to the different combination mode of the cell, and countless groups of programming files can be stored.

4. After setting the parameters, start the detection mode with one key.

5. The function setting is simple, easy to understand and operate, without on-site training.

6. The IPC supports the function of sudden power failure, and the database works normally.

7. Mass storage of product parameters and direct detection of parameters.

| Item | Parameter |

| Power supply | AC220V,50Hz |

| Power | 600W |

| Suitable cell | Prismatic cell |

| Inspection size | 400*300mm, customizable |

| Inspection degree | 360 degree |

| Inspection speed | 100 pcs/1.5s |

| Inspection accuracy | 100% |

| Size | 900*720*1600mm |

| Weight | 80kg |